This guide explains how to design, install, and maintain busbars so your off-grid battery compartment runs cool, stays safe, and is easy to service.

Open the hatch and picture it: cables crossing at odd angles, stacked lugs on every stud, and copper that already looks tired and dull. That chaos is not just ugly; it is where heat, false BMS readings, and early battery death quietly begin. Case studies from busbar and battery manufacturers show that disciplined design and maintenance can slash failure rates and stretch service life, especially when combined with smart monitoring. The good news is that you can apply the same principles in your own system to build a compartment that is both beautiful and brutally reliable, step by step.

From Spaghetti to Sculpture: What "Work of Art" Really Means

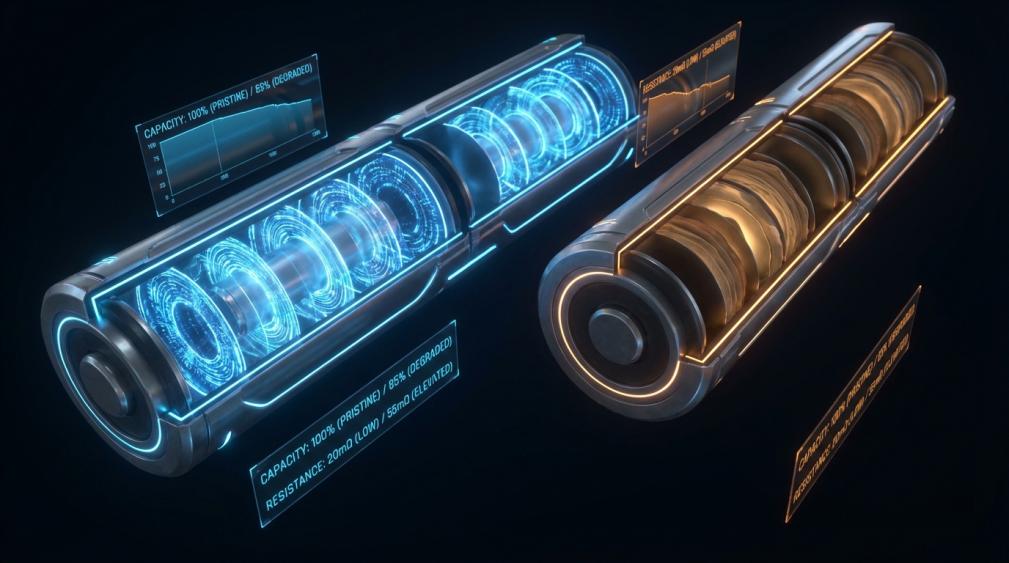

In a lithium bank, busbars are the solid metal strips that tie cells, batteries, and power electronics together. Compared with loose cables, well-chosen and well-placed busbars shorten the current path, reduce resistance, and stabilize the whole pack, as described in design notes from Shogo Busbar and Rogers Corporation. That is the foundation for a compartment that runs cool and predictable instead of hot and temperamental.

A "work of art" battery bay is not about fancy covers or LED strips. It means current flows through short, direct paths, each parallel battery sees the same share of work, and the joints are accessible enough that you can put a wrench or meter on anything in minutes. Shogo Busbar emphasizes that busbar size and cross-sectional area must match the rated current to avoid overheating and that connection geometry should maximize contact area. When that is paired with a tidy physical layout, you get a compartment that looks calm even when you are pulling hard loads.

Good design also supports your battery management system. Orion BMS troubleshooting guidance points out that loose terminal-to-busbar joints and high-impedance connections create false low-cell readings under load and serious fire hazards. A visually clean, mechanically solid busbar layout makes it much easier to track down a bad joint before it becomes a cooked joint.

Choosing Busbars That Run Cool, Not Just "Big Enough"

Material Matters: Copper, Aluminum, and Hybrids

Picking the metal is your first big decision. Busbars are usually copper or aluminum, and some advanced packs use copper-nickel hybrids. BatteryDesign.net and Rogers Corporation describe how each material changes your thermal, electrical, and weight budget.

Here is the practical comparison you need when staring at catalogs or scrap bins:

Busbar material |

Key strengths |

Key compromises |

Best use cases from industry notes |

Copper |

Very high conductivity, excellent heat spreading, compact for a given amp rating |

Heavier, more expensive, surface oxidizes and needs plating or protection |

High-current EV busbars, tight spaces, fast-charging modules, compact energy storage |

Aluminum |

About half the weight of copper and cheaper, good when space is generous |

Needs roughly twice the cross-section for similar performance, higher thermal expansion, more careful joint design |

Lightweight packs and modules where you can afford thicker bars and want to save weight and cost |

Copper-nickel composite |

Copper core with nickel surfaces gives high conductivity plus great corrosion resistance and weldability |

Highest fabrication cost, interface stresses must be managed |

Pouch-cell packs, vibration-prone ESS modules, demanding long-life applications |

For cramped off-grid compartments where you are fighting every inch and still want high surge capacity, notes from Rogers Corporation and BatteryDesign.net make copper the obvious first choice. Nickel or nickel-clad designs shine more at cell-tab level or in OEM packs focused on manufacturability and corrosion control, not so much in a retrofit where bar count is low and access is good.

Whatever you choose, you are not just picking metal; you are picking how confidently that compartment will shed heat when the inverter is pushing near its limits on a hot afternoon.

Sizing for Real Current Instead of Spec-Sheet Fantasy

The next decision is sizing, and this is where many DIY battery bays go from "usable" to "problem child." Wellgo Battery's design brief on busbar failures highlights undersized cross-sections as a primary cause of local heating, voltage drop, and damaged plating. Their recommendation is to design for current density around 1,300-1,900 A per square inch of conductor cross-section.

Shogo Busbar adds the simple but often ignored rule that busbar cross-section must match the rated current to keep long-term operation reliable. That means you size the metal for the actual current that section of bar will see, not just for the nominal load of one device.

Consider a common off-grid scenario from a coffin-style 12-battery build discussed on Solar Electric's forum. Each 100 Ah lithium unit is rated for about 100 A, which suggests a theoretical 1,200 A if you somehow pulled maximum from every battery at once, plus about 200 A of potential charge current from charge controller and inverter chargers. The user feeds all of this through a single 250 A DC breaker. Even without the final community answer, the right conclusion is clear: the breaker sets a limit at its location, but upstream busbars that tie batteries together can still see much higher fault or imbalance currents.

A practical way to think about this is to walk the current path mentally. The bar that connects all positive posts before the breaker must be sized to stay cool if one battery or cable is slightly weaker and others carry a little extra. Using the Wellgo current-density guideline, a 250 A section needs enough cross-sectional area to keep current density within that 1,300-1,900 A per square inch range. If you expect higher transient or imbalance currents at that point, you move up in cross-section, not down.

At the same time, Anern's balance-of-system guidance reminds you that system voltage changes everything. Running 48 V instead of 12 V cuts current for the same power, which allows smaller copper, shorter runs, and lower wiring cost. If you already know you are bumping into busbar size limits, one of the cleanest design fixes is to run a higher system voltage, which immediately makes both busbar and cable management more forgiving.

The takeaway is simple. Start with the worst-case realistic current for each bar segment, not just the nameplate rating of a breaker. Design cross-section using an honest current density target like the Wellgo range, and then look at your compartment space to choose width and thickness that maintain that area.

Layout and Connections: The Secret to a Calm, Cool Compartment

Once you have the right metal, turning a messy bay into a work of art comes down to routing and joints.

Short, Straight, Symmetrical Paths

Shogo Busbar describes busbars at cell, module, and pack level as a way to keep current paths short, resistance low, and voltage balanced. That same principle transforms a retrofit. Cables that snake across the bay add resistance and clutter; straight busbars that follow the rows of batteries create a visual grid that carries current cleanly.

Anern's DIY solar balance-of-system article stresses that bad physical layout and long cable runs quietly inflate cost and voltage drop. The same is true inside the box. Pack the inverter, charge controller, and battery bank close together so your heavy-gauge links are as short as possible. Keep positive and negative busbars parallel and close, which reduces loop area and stray inductance, aligning with busbar layout best practices discussed in Rogers Corporation's EV battery pack guidance.

Symmetry matters when you parallel multiple batteries. If the first and last batteries see different path resistance because of lopsided bar routing, they will not share current evenly. That is how supposedly identical units age differently. A layout where every positive and negative path is mirrored side to side keeps each battery pulling its fair share, extending the life of the whole bank.

Joints and Torque: Where Most Failures Begin

Every joint is a potential heater. Wellgo Battery's review of busbar design failures shows that poor laser or ultrasonic welds, voids in joints, and loose mechanical fasteners cause microvibrations and local hot spots that can literally melt connectors. They recommend non-destructive inspection for critical packs and treating any joint with more than about 100 microohms of contact resistance as a rework candidate.

Copper busbar maintenance guidance from a major manufacturer reinforces this with field examples. In one long-running data center, thermal imaging after years of service found a dozen hidden defects. By replacing a handful of flexible connector sets and adding intelligent monitoring, they cut downtime by about 83% and extended busbar service life to roughly 20 years, showing that attention to seemingly minor joints can extend life by three to five times and cut failure rates by more than 90%.

In a smaller off-grid compartment, your inspection toolkit is simpler but the logic is identical. Every bolted joint should be flat, clean, and tightened to a controlled torque, not "until the wrench feels about right." The same manufacturer recommends retightening bolts on a schedule and using visual torque markings so you can see if anything has shifted. Orion BMS troubleshooting notes warn that even a loose terminal that still looks fine can introduce enough resistance to cause false low-voltage readings under load and dangerous local heating at that stud.

Think of each busbar joint as a fuse you do not want to blow. If anything looks discolored, smells hot, or shows a temperature spike under load, treat it as a fault, not a cosmetic issue. In their maintenance guide, one copper busbar vendor describes correcting an unexpected temperature rise of about 15°F at a joint by de-energizing, regrinding the contact surface, applying conductive paste, and recalibrating bolt torque.

That same disciplined repair approach belongs in a serious off-grid compartment.

Clean, Protect, and Monitor: Keeping It Beautiful for Years

A gorgeous busbar install can quietly degrade into a rough, high-resistance mess if you never clean or check it. Long-term performance depends as much on environment and maintenance as on initial design.

Cleaning Without Damaging the Finish

New Energy GN's guide on cleaning copper busbars makes a simple point: dirt, oxidation, and corrosion all raise contact resistance and cut efficiency. They recommend different levels of cleaning depending on the problem. For light dust, fully de-energize the system and wipe with a dry cloth or soft brush. For greasy films or minor contamination, isopropyl alcohol works well and evaporates quickly, reducing moisture risk.

For heavier oxidation, they describe carefully using fine abrasives or copper cleaning solutions, followed by thorough rinsing and drying. LiFePO4 maintenance tips from EVLithium echo the same idea at the battery level: treat oxidized terminals and busbars with a deoxidizer or mild acid plus a soft brush, but never attack them with brute force that removes too much metal. In all cases, the non-negotiables are to disconnect loads first, wear insulating gloves, and confirm everything is dry before re-energizing.

In humid or coastal environments, the busbar maintenance guide suggests using tinned or coated copper and storing bars away from corrosive gases. For an off-grid compartment, that translates into picking tinned copper where possible and ensuring the bay is dry and ventilated so you are not fighting condensation and rust every season.

Monitoring Temperature and Resistance Like a Pro

You cannot manage what you never measure. The copper busbar maintenance source recommends installing infrared temperature labels or wireless sensors at joints and corners, using alarm thresholds based on insulation class. While their exact temperature bands are tailored to large industrial systems, the underlying lesson is universal: know what normal temperature looks like for your compartment at a given load, and alarm on deviations rather than absolute numbers.

That same document outlines periodic preventive testing, including insulation resistance and loop resistance checks, along with advanced tools like ultrasonic partial discharge detection for larger systems. In an off-grid bay, even a simple infrared thermometer scan during a heavy load tells you a lot. If one link runs noticeably hotter than its neighbors, that joint or bar deserves immediate inspection.

BatteryDesign.net and Wellgo Battery both stress that even milliohm-level differences in resistance add up across thousands of joints in a high-voltage pack. In a smaller system, you have far fewer joints, but each one is proportionally more important. Document your readings when the system is new, repeat the measurements at least yearly, and treat changes as early warning signs instead of waiting for a trip or failure.

Safety: The Invisible Frame Around Your Artwork

A beautiful compartment that is unsafe is just a polished hazard. Busbar and BMS safety guidance converge on three pillars: controlled procedures, adequate protection, and respect for standards.

The copper busbar maintenance guide recommends a strict disconnection sequence before any work: open the load side first, verify absence of voltage, ground the system, and set physical barriers. It also highlights personal protective equipment such as high-voltage insulated gloves, arc-rated face protection, and flame-retardant clothing. Those habits belong just as much in a cabin or van as in a substation.

On the higher-level system side, eInfochips' overview of safety standards for battery management systems shows how serious the industry is about fault control. Standards such as UL 1973 and UL 9540 for stationary energy storage and NFPA 855 for fire protection treat busbar faults, ground faults, and thermal runaway as central hazards. Even if you never send your DIY system through formal certification, you can copy the mindset: provide clear overcurrent protection, maintain solid insulation and creepage distances, and assume that any hidden fault may fail in the worst possible way.

Wellgo Battery's discussion of past incidents, including aircraft and consumer electronics packs where lack of clearance and missing insulation tape contributed to thermal runaway, makes the cost of casual workmanship brutally clear. Good busbar management is not just about shaving a few watts of loss or making the bay look impressive on social media. It is about giving every cell the safest possible environment to deliver energy for many years without ugly surprises.

FAQ

How often should I inspect and clean busbars in an off-grid battery compartment? Busbar maintenance guidance for industrial systems suggests monthly light cleaning in dusty environments and deeper cleaning a few times per year. In a typical off-grid bay that is reasonably sealed, a practical pattern is to perform a quick visual and temperature check whenever you are already servicing the system, and a more thorough inspection with cleaning and torque checks at least once a year, borrowing from the periodic tightening and testing schedules used in copper busbar systems.

Is it worth upgrading from cable bundles to solid busbars in an existing battery bank? Shogo Busbar and Rogers Corporation both emphasize that busbars provide shorter, more stable current paths and better mechanical robustness than ad hoc cable bundles. If your existing compartment has multiple parallel cables on each terminal, inconsistent lengths, and hard-to-access joints, upgrading to properly sized and laid-out busbars can reduce resistance, improve current sharing between batteries, and make future maintenance far easier. The improvement in safety and serviceability is usually worth the effort when you are already planning a rewire or battery upgrade.

Do I really need monitoring hardware for a small system, or is a clean visual layout enough? Visual order is a strong start, but experience from data center busbar maintenance and BMS troubleshooting shows that many defects are invisible until they heat up under load. Even a couple of inexpensive temperature stickers on critical joints or a handheld infrared thermometer can bring your small system much closer to the disciplined monitoring used in large installations. Think of monitoring as inexpensive insurance that protects the craftsmanship you have put into your compartment.

A tidy, cool-running busbar layout is not an aesthetic luxury; it is the backbone of a safe, resilient power system. Treat every bar and joint as a deliberate design choice, not a leftover piece of copper, and your battery compartment will look and perform like a professional build long after the novelty of your latest upgrade has worn off.

References

- https://www.batterydesign.net/engineering-efficient-current-paths/

- https://www.fjinno.net/switchgear-bus-complete-guide-to-busbar-systems-monitoring-maintenance/

- https://www.slideshare.net/slideshow/various-busbar-arrangements/141260832

- https://rpk-global.com/busbar-efficiency-and-safety-for-electric-vehicles

- https://secondlifestorage.com/index.php?threads/mistake-busbars.2322/

- https://batterypackdesign.com/busbar-fabrication-tolerances-and-gdt/

- https://busbarmanufacturer.com/maintaining-copper-busbars-guide/

- https://chinanusaiger.com/5-common-busbar-installation-mistakes-and-how-to-avoid-them/

- https://www.evlithium.com/Blog/lifepo4-battery-maintenance-tips.html

- https://shogobusbar.com/the-role-of-busbars-in-connecting-battery-cells/

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.